RS series (adsorption printing die cutter slotter folder gluer production line )

- Commodity name: RS series (adsorption printing die cutter slotter folder gluer production line )

- Commodity ID: a12

- 产品描述

-

Function and characteristic:

● Connection with the printing machine, printing, sltting, die cutting, gluing, folding, correction, counting, palletizing, packing, output

● Machine connection control, computer storage order, remote control operation, digital input.

● Key transmissions adpot imported brand bearings and high-speed transmission belts.

● Total power of spraying, folding and gluing parts: 52kw Packing parts: 3kw Total weight of the machine: 23T.

● Sticky box: 12*4 meters Packing: 5*2.5 meters.

● Gluing part: The latest generation glue spraying system,Can automatically tracks and non-contact accurate glue spraying without any serrings, resist corrosion and evenly spray or glue.

● Electrical appliances: All adopt international top brand (Siemens), 9 servo control system, servo driver adopts international top brand (British CT). stable quality, can be designed and manufactured according to requirements. This machine can process 2-8mm three -layer, five-layer corrugated cardboard.

Technological parameter

Model RS920 RS1224 RS1228 Maximum machine speed(piece/min) 350 250 220 Maxi feeding size(LX Wmm) 900x2000 1200x2400 1200x2800 Min feeding size(mm) 300 350 Min fold size (mm) 240×110 250x110 Suitable for boardsheet (mm) E-AB ridge * Subject to change and improvement without notice.

Counter-Ejector Section

★ Adopt photoelectric swich to count accurately.

★ Adopt photoelectric swich to count accurately.

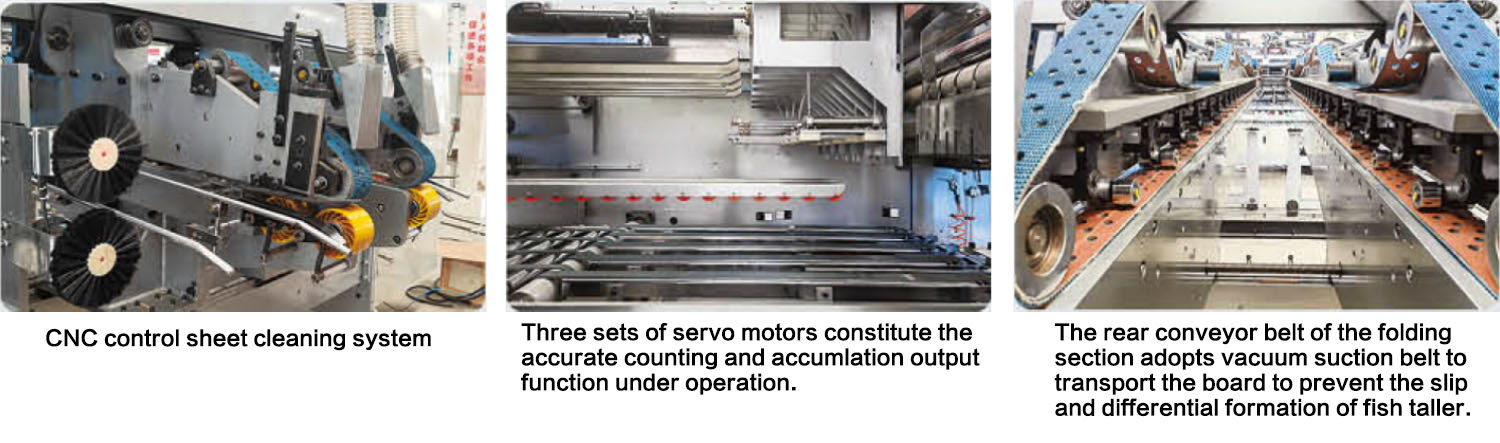

★ Three sets of servo motors constitute the accurate counting and accumlation output function under operation.

★ Servo controlled high speed separating rod ensures counting and stacking as required.

★ Pneumatic auxiliary board receiving rod is adopted to make the carton stacking more smooth.

★ Pneumatic pushing mechanism discharges the stacked carton neatly.

★ The strong wind pressure device prevents the carton from lifting up when output from the folding section ensuring the stacking is neat and the direction of the vent can be deflected at will.

★ The rear bafle part can be adjusted elecrically (automatically or manually) back and forth according to the size of the board.

★ Equipped with cushion rubber pads to reduce the impact on the edge of the carton at high speed and prevent the carton from buing danaged.

★ The upper and lower conveyor belts output the whole bundle of cartons synchronously.

★ The position of upper conveyor belts in the height direction is automatically (or manually) adjusted by the lifting mechanism, and the eight changes accordingly according to the quantity setting of cartons per bundle.

★ The output section can move left and right as a whole to ensure that the carton always flls in the center of the machine.Folding Section

★ Upper and lower beam belt speed and slotting machine speed co-adjust, and paste folding belt and conveyor belt and slotting machine speed is very close, can avoid the problem of paste box line and slotting machine grab or block paper, more accurate paper;

★ Upper and lower beam belt speed and slotting machine speed co-adjust, and paste folding belt and conveyor belt and slotting machine speed is very close, can avoid the problem of paste box line and slotting machine grab or block paper, more accurate paper;

★ Upper and lower belt speed can be adjusted separately, that is, when the upper and lower belt speed is different, it can be adjusted to the same.

★ Origami paper is easy to adjust the angle of origami with belt and rubber stick.Spray glue system(optional)

★ Cooperate with international well-known brands of glue spraying system suppliers to ensure good after sales service

★ Cooperate with international well-known brands of glue spraying system suppliers to ensure good after sales service

all over the world.

★ Use the latest generation glue spraying system,Can automatically tracks and non- contact accurate glue spraying without any serrings.

★ Environmentally friendly, No need to worry about leaking or spilling glue, Less waste, More convenient to maintenance

and adjustment.Power electrical depapment

★ The main power adopts frequency conversion motor,which is synchronized with the flexo printer.

★ The main power adopts frequency conversion motor,which is synchronized with the flexo printer.

★ All powers are driven by synchronous belt,Simple structure,stable operation,Lower noise and lower vibration.

★ The moving part are composed of ball screw rod and linear guide.

★ Electrical appliances all adopt international top brand (Siemens), 9 servo control system, servo driver adopts international top brand (British CT), stable quality, can be designed and manufactured according to requirements. This machine can process 2-8mm three-layer, five -layer corrugated cardboard.

Product inquiry

NOTE: Please leave your email, our professional person will contact you asap!