ZYKM-B series (upper / roller to roll transmission)

★ Keyless conntection ring to reduce center wear ,imaginary magnification .to maintain longterm printing registration .

★ Lubricate oil balancer : to keep the unit lubricating oil on the same level .

★ The whole machine computer control ,PLC touch screen

★ Computer remote maintenance

★ Each unit equippment alarm bell and emergency stop bottom

- Commodity name: ZYKM-B series (upper / roller to roll transmission)

- Commodity ID: a6

- 产品描述

-

Main featrues:

● Control on the main console and each unit console with display adjustment system, store repeated order, easy for operation.

● Motorized printing plate mounting.auto reset, quick change.

● Each unit is equipped with Emergency Stop switch to ensure safety operation.

● Motorized gap adjustment device for ease operation.

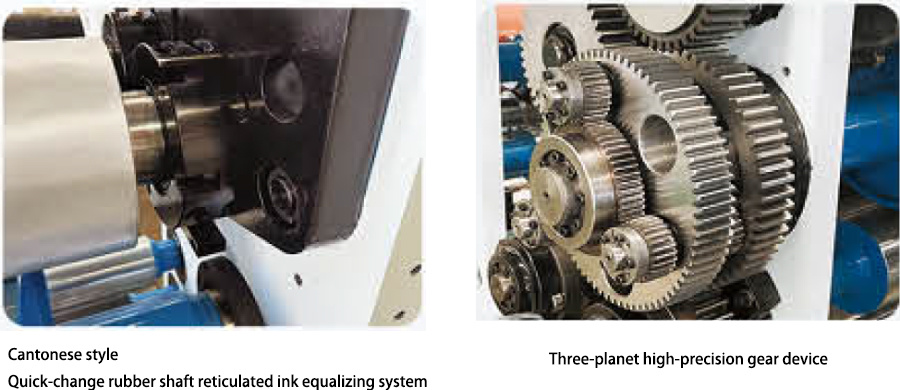

● Transmissions are using precision high hardness gears with spraying type circulating lubrication system.

● Electric element,bearing,and pneumatic element all us international brand.

Technological parameter

Type/Project ZYKM-B

920ZYKM-B

1224ZYKM-B

1228ZYKM-B

1424ZYKM-B

1428ZYKM-B

1624ZYKM-B

1628ZYKM-B

1632Maximum speed(piece/min) 200 180 150 150 120 150 120 120 Paper feeding precision ( mm ) ±1.0 ±1.0 ±1.0 ±1.0 ±1.0 ±1.0 ±1.0 ±1.0 Maximum feed size ( mm ) 900×2100 1200×2500 1200×2900 1400×2500 1400×2900 1600×2500 1600×2900 1600×3300 Minimum feed size ( mm ) 280×600 350×600 350×600 400×600 400×600 450×600 450×600 450×600 Size of drawing paper ( mm ) 1200×2100 1500×2500 1500×2900 1700×2500 1700×2900 2000×2500 2000×2900 2000×3300 Maximum printing area ( mm ) 900×2200 1200×2400 1200×2900 1400×2500 1400×2900 1600×2500 1600×2900 1600×3200 Printing set ( mm ) ±0.5 ±0.5 ±0.5 ±0.5 ±0.5 ±0.5 ±0.5 ±0.5 Thickness of standard printing plate ( mm ) 5mm 5mm 5mm 5mm 5mm 5mm 5mm 5mm Minimum slotting interval (mm) Positive knife 140×140 140×140 140×140 140×140 140×140 140×140 140×140 140×140 Scalpel 215×70 215×70 215×70 215×70 215×70 215×70 215×70 215×70 Maximum groove depth ( mm ) 225 300 300 350 350 400 400 400 Slotting accuracy ( mm ) ±1.5 ±1.5 ±1.5 ±1.5 ±1.5 ±1.5 ±1.5 ±1.5 Die cutting precision (mm ) ±1.5 ±1.5 ±1.5 ±1.5 ±1.5 ±1.5 ±1.5 ±1.5 Lead feeder unit

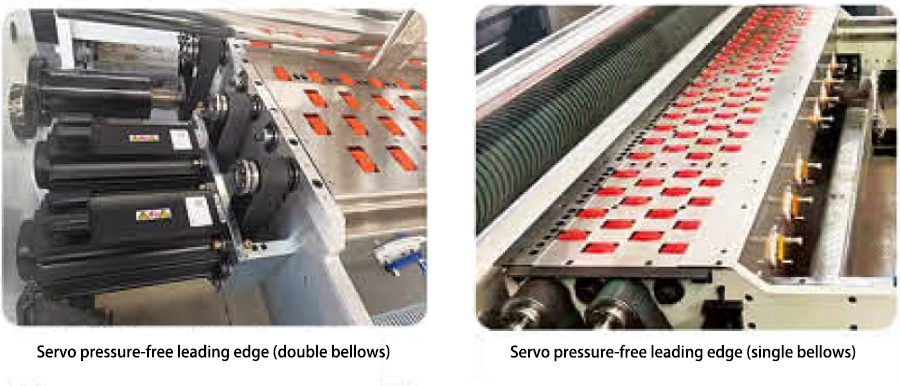

★ Extended wheel type lead edge feeder with servo driving system and vacuum assist for high feeding precision and running steadiness.

★ Extended wheel type lead edge feeder with servo driving system and vacuum assist for high feeding precision and running steadiness.

★ Suitable for 3/5/7ply boards and micro- flute board of E.W.F flutes.

★ Vacuum with variable strength and sectional adjust for different board qulity and sizes.

★ Motorized leftright for side gauges.

★ Dupiex feeding rolls with spring pressure for minimized board caliper loss.

★ Brush and vacuum suction to clean dust from board surface for perfect printing result (Optional electrostatic dust remving devce).

Printing unit

★ PLC computerized precise printing registration with touch screen and altermative motorized control .

★ PLC computerized precise printing registration with touch screen and altermative motorized control .

★ Motorized digital control for printing clearance adjust from 0- 12mm.

★ Motorized digital control for inking gap between rubber roll and anilox roll from 0- -6mm. (Optional ceramic anilox roll with doctor blade).

★ Pneumatic up/down &auto idle rumming of anilox roll to avoid ink drying.

★ Ruber roll and anilox roll with quick-change structure.

★ Foot switch and ratcher wheel locking system for fast fixeo plate mounting.

★ Board conneying wheels with fast moving systom for fast flexo plate mounting.

★ Boar conveying wheels with fast moving and locking struture.(Optional PLC computerized vacuum transfer system)

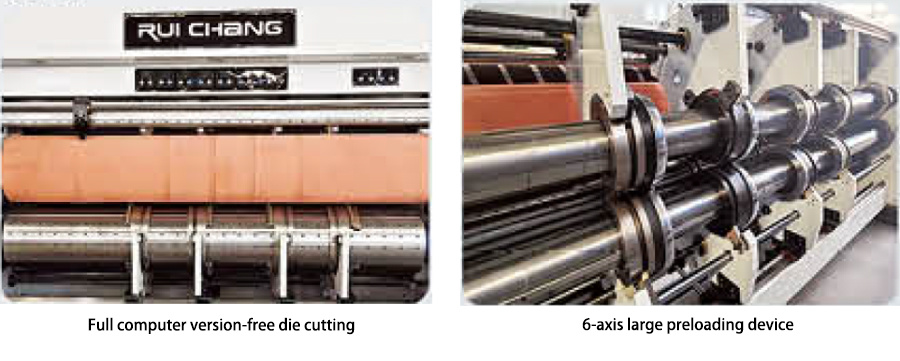

Die cutting unit

★ Die-cutting pressure gap is motorized adjust

★ Die-cutting pressure gap is motorized adjust

★ Setting displacement measure device for anvil roll.

★ Quick change over rubber anvil, good wear-ability.

★ Speed difference compensation system make line speed be synchronization, it can ensure die cutting precise.

★ Anvil roll renew device to prolong usage time of anvil roll and reduce production costs.

Product inquiry

NOTE: Please leave your email, our professional person will contact you asap!