RS-Full vacuum transfer printer series

★ Keyless conntection ring to reduce center wear ,imaginary magnification .to maintain longterm printing registration .

★ Lubricate oil balancer : to keep the unit lubricating oil on the same level .

★ The whole machine computer control ,PLC touch screen

★ Computer remote maintenance

★ Each unit equippment alarm bell and emergency stop bottom

- Commodity name: RS-Full vacuum transfer printer series

- Commodity ID: a4

- 产品描述

-

Main featrues:

● The whole machine is designed according to the high demand, reliability function and safety

production.● Selects the high quality materials and accessories, all the drive rollers adopted high quality steel

materials, hard chrome plating and the surface surface grinded.● Fixed units, each unit adopts the vacum adsorption type conveyer, printing unit topping adopts servo

control, to achieve precision printing network.● The machine adopts PLC touch screen control, can be stored and reuse the ordered data, it can

change rapidly ,operate more convenient.● Remote detection of faults can be realized through the network, and equipment faults can be quickly

eliminated.● Automatic zero and automatic reset.

● Transfer roller impression cylinder, the clearance of anilox roller is controlled by computer.

● It adopt the paper central dust collection system.

Technological parameter

Type/Project RS920 RS924 RS1224 RS1228 Maximum speed (piece /min) 350 280 250 230 Maximum feed size(mm) 900x2100 900x2500 1200x2500 1200x2900 Minimum feed size(mm) 300×600 300×600 350×600 350×600 Size of drawing paper(mm) 1200×2100 1200×2500 1500×2500 1500×2900 Maximum printing area(mm) 900×2000 900×2400 1200×2400 1200×2800 Thickness of standard printing plate ( mm ) 7.2 7.2 7.2 7.2 Maximum die size ( mm ) 900×2000 900×2400 1200×2400 1200×2800 * Subject to change and improvement without notice.

Lead feeder unit

★ Paper feeding can be continuous or skip paper ( with counter).

★ Paper feeding can be continuous or skip paper ( with counter).

★ It adopt the lead edge roller to feed ,can adjust the route ,to ease the pressure on drawing paper roll.

★ Lead edge feeding increase the section flow rate to meke feeding smoothly and accuracy.

★ Frequency conversion control vacuum alir flow and pressure, to match the board size.

★ Paper feeding rubber roller with soft inner and outer hard, keep the inner elastic and guarantee the surface wear resistance, reduce the cardboard was be squashed to be be sent in.

★ Dust cleaning device:The brush and blower to remove cardboard surface confeti.Multiple fan stralight smoke added electrostatic brush and tuming round brush, the grealest degree remove dust board surface.

★ About paper roller clearance, the position of the left right bar is adjusted by computer.

★ Equipped with brush device to sufficiently eliminate dust and scraps as well as forelign substances on the printing surface and to improve printing quality.

Printing unit

★ Scroll hanging version,locking 360 degrees, let operation of hanging plate is simple, more accurate registration.

★ Scroll hanging version,locking 360 degrees, let operation of hanging plate is simple, more accurate registration.

★ Changing plate quickly,it can fix the incline error when paste the plate, 80 that reach to the range of amendment.

★ Adopting vacuum absorb and high precision to convey, high Printing precision.

★ The fixed group be wlden in printing unit,t can help dry the ink, to guerantee the printing precision.

★ Printing roll phase adopt servo motor to drive,can connect to the Endat high precise encoder,guarantee the control precision of the servo drive system, topping-control contact to the servo directly, quick response and high precision.

★ The transverse phase ,computer and electric- -digital control.

★ Imported brand scraper ink system: ink cavily body for non- -metal material, special never rust, easy to clean;Rapid change around the blade.

★ Adopt automatic cleaning - switching device Let the ink recycling more thoroughly and save the ink,when clean or change the color of the ink,can save ink 0.4- 0.5kg per unit once.

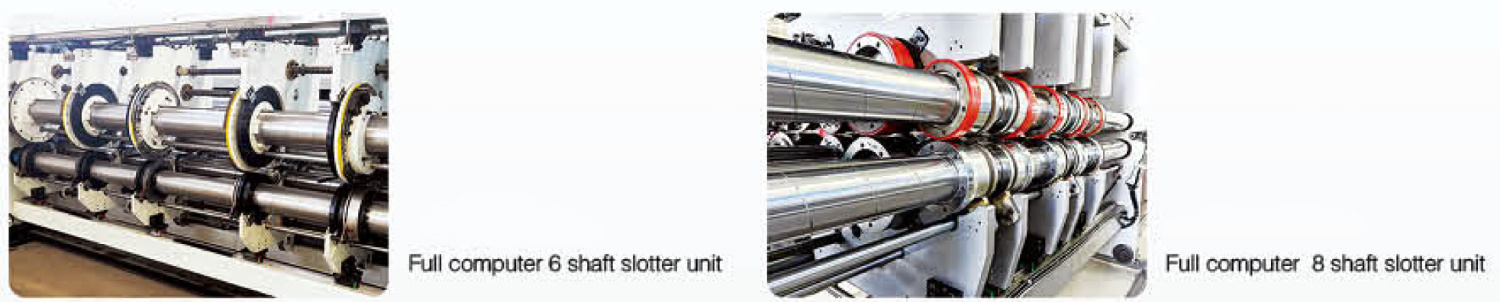

Slotting unit

★ Pre -pressing device; Electically couped slotting and cutting and prepressing

★ Pre -pressing device; Electically couped slotting and cutting and prepressing

★ Automatically adjusted group data setting with frequency converter revision to ensurehigh precision.

★ Manually adjusted scoring wheel clearance with adjustment data displayed on the dial.

★ 7mm alloy steel scoring knives with indent heat treatment to enable grinding teeth shaip edge and high precislon.

★ PLC, touch screen and motorized digital 360degree adjustment adopted lorm solting phase with order being able to stored.

★ Additional portable orfice dile backer.

★ Equlpped with the inerlock control switch at slotting unit to achieve stop orresumepaper feed,

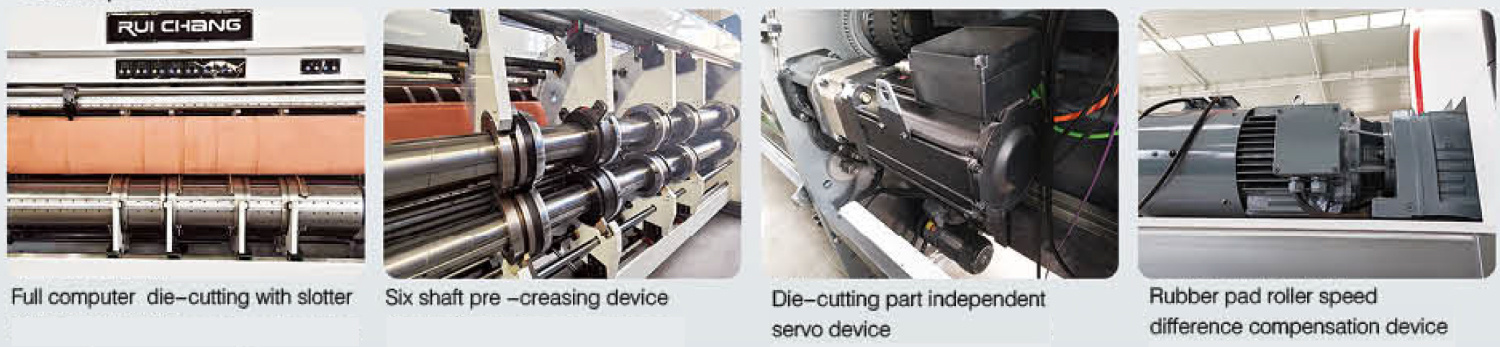

Die cutting unit

★ With the servo motor drive,guarantee the shake of printing unit is few,to make print accurate.

★ With the servo motor drive,guarantee the shake of printing unit is few,to make print accurate.

★ Rubber gasket roll compensation is controlled by independent motor drive, rubber mat roller speed, compensation scope±3.5 mm, make the rubber gasket roller and die cutter roller speed is consistent.

★ Rubber gasket roll machine screw reversing 50 mm winding device, improve the service life of the rubber gasket.

★ Transverse phase, computer and electric control, digital control in the plus or minus 10 mm

★ Die-cutting phase adjustment by PLC, servo drive.

★ The structure of the rubber gasket roller, keep the rubber gasket surface lis fiat and level.

Product inquiry

NOTE: Please leave your email, our professional person will contact you asap!